Crack Mcu Most Important Two Steps

Crack Mcu Most Important Two Steps

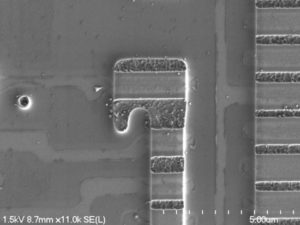

Crack Mcu need to use Focus Ion Beam to make the necessary modification on the mcu, and hereby we would like to introduce these two steps separately, through inject the iodin steam can have a better corruption rate of crack mcu. Cracker can produce the metal layer windows on the bottom of mcu for visiting without damage the coherent structure. Through the injection of organic gas with platinic can create the new connection on the mcu crack. use other chemical component like isulators can download the ion beam into the bottom metal of mcu and make connection with the surface metal when crack mcu without get in touch with other cover layer. Focus ion beam can move on the surface of mcu with 0.1 micron preciseness regardless the mcu surface structure and evenness. Use the infrared line for imaging and can locate the transistor on the mcu from it back when crack mcu.

After we made some necessary electrical connection and cut out on the mcu for crack purpose, we need to do it’s the modification on the mcu circuit pattern when crack it. As we all know, it is not necessary to have the information from databus internally of mcu crack by using the microprobe technology. Sometimes, especially for the mcu itself, cut off the metal interconnection wire or break the control circuit when crack mcu to seal off the security protection mechanism. Focus Ion Beam is very easy to re-connect the protection security states transmission wire to the ground or power supply layer when crack mcu. Although microprobe can do the same work but it won’t work if the metal wire embedded very deeply.

Mcu crack and modification at least need to find out the crack point through the reverse engineering process which means the job can’t be done by a cracker with less experience and well equipped facilities.

Tags: mcu dump archive cracking,mcu dump code cracking,mcu dump content cracking,mcu dump data cracking,mcu dump eeprom cracking,mcu dump file cracking,mcu dump firmware cracking,mcu dump information cracking,mcu dump memory cracking,mcu dump program cracking